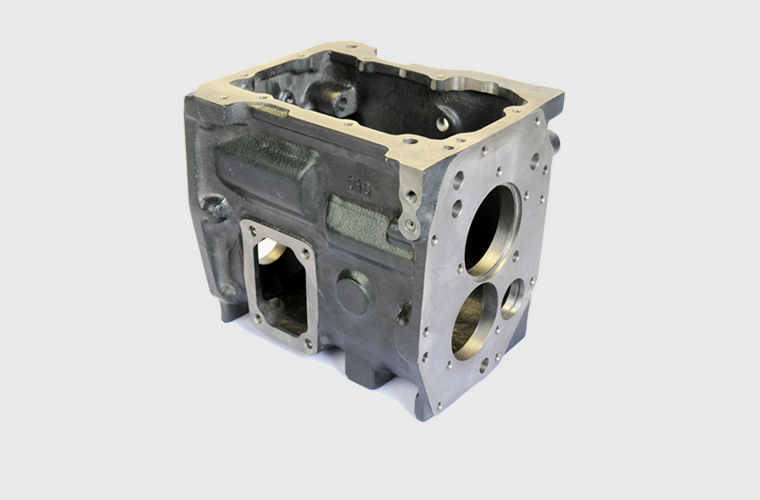

Raj Techno Metallics foundry division is an ISO 9001:2015 certified company.We manufacture small to medium sized castings and medium to high volume castings in Grey Iron and S G/Ductile Iron.

Our team, infrastructure & processes are capable to produce SG Iron and intricate Grey Iron Castings at high precision. Raj Techno Metallics have in-house machining facility which is designed to cater a variety of size, weight and volume requirements.

We have an expertise team, best infrastructure and processes to produce SG Iron and intricate Grey Iron Castings at high precision.

We are equipped with modern facilities like Cold Box Machines, Shell Core Shooters , Spectrometer, Induction Melting, Internal Shot Blasting, Casting Inspection Facilities like Mechanical Testing Equipment, Hardness Testing, Microstructure Testing and CMM for Machined Component Inspection.

Green Sand Moulding Foundry Capability

CASTING MATERIAL

- Cast Iron Grades: FG-200, FG-220, FG-260, FG-300

- Ductile Iron Grades: 400/10, 450/12, 500/7, 600/3 and 700/3

CASTING RANGE

- Weight: 1 Kg to 50 Kg

ANNUAL VOLUME

- 5000 Metric Ton / Year

VALUE ADDTION

- Painting, Coating

- Machining, Phosphating

- Plating

- Leakage Testing,Heat Treatment

Mr. B. L Patil: 9371159595, Mr. S. D Potdar: 9890144177

Products We manufacture

Our Products

Our Foundry Infrastructure

Moulding

We are using CI fix boxes having sizes 20 x 20, 20 x22, 24 x 28 inch.

Melting

At the melting section, we have Inductotherm make Induction Furnace of 550 Kw with 500 kg melting capacity.

The melting section have online Carbon Silicon Analyzer and molten temperature measurement facility

Pouring System

- Car track with 90 Pallets for pouring of green sand & shell moulds

- Pouring ladle movement with the help of monorail

- Up-Down movement of the ladles is carried with help of wire rope Crane

- We have Various ladles from 250kg to 300Kg

- A Magnesium Treatment Ladle having 300 kg capacity with Tundish cover

- Geared Pouring ladles having capacity of 250 kg capacity

Fettling

We use the following types of equipment for removal of runner, risers & for the finishing of castings

- Shri Shakti, Coimbatore make Hanger type Double door Shot Blasting machine

- 16” Pedestal Grinder

- Pneumatic Pencil Grinders

- Casting painting made by dipping process and spray